Tuning the elastic properties of metal-organic frameworks: between crystal breathing and mechanical robustness

Tuning the elastic properties of metal-organic frameworks: between crystal breathing and mechanical robustness

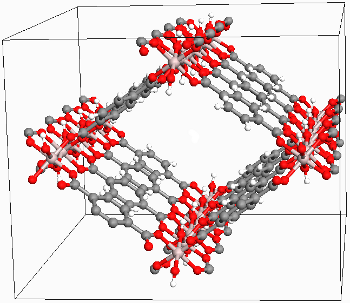

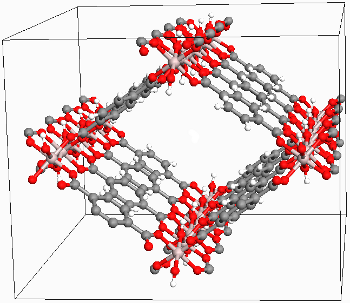

Promotor(en): V. Van Speybroeck, A. Ghysels /15_NANO14 / Solid-state physics, Model and software development, Nanoporous materialsMetal-organic frameworks (MOFs) are crystalline materials that consist of metal oxide clusters connected by organic linkers. This results in 1D, 2D or 3D repeated structures with large cavities, i.e. periodic porous structures. The pores allow confining chemical species for several cutting-edge applications, such as gas storage, gas separation or catalysis. To obtain an efficient MOF, not only pore sizes and reactive centres are important, however, but also finely tuned elastic properties. This makes it possible to choose between a flexible or a rigid framework, depending on the application.

Indeed, contrary to most crystalline materials, some MOFs are also very flexible. Researchers discovered the adsorption of guest molecules to cause drastic deformations of the framework. This phenomenon was called the 'breathing' of the MOF, as the structure expands (large pore) or collapses (narrow pore), leading to large variations in pore size. Moreover, it was later found that breathing can also occur without guest molecules, but because of stimuli like pressure and temperature [1].

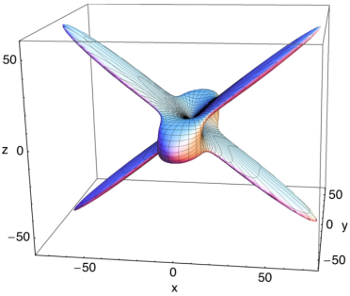

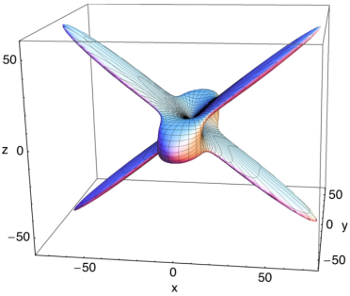

In literature, it has already been established that the breathing of metal-organic frameworks can be linked to an anisotropic stiffness of the large-pore crystal [2]. The material is easily deformed in one direction, but not in another. Because of this directional flexibility, the barrier between the expanding and collapsing of the pores remains small, enabling the breathing of the MOF. By screening new MOFs for such a characteristic anisotropy, the breathing behaviour of a MOF can therefore already be estimated without experimental synthesis.

On the other hand, industrial processability is essential too. Commercial applications require MOFs to retain their structure during shaping or post-synthetic processing. Very rigid frameworks are better able to withstand external pressure or friction, maintaining their porous structure throughout the processing of the material. This is an important criterion for non-breathing MOFs.

Goal This Master's thesis aims to accurately predict the elastic properties of potential MOFs. To do this, you will use both quantum-physics-based density-functional theory (DFT) (slow yet accurate), and in-house developed classical force fields [3] (fast yet with limited transferability). Ideally, your thesis will allow you to calculate accurate elastic constants for a range of MOFs, either by fine-tuning DFT calculations or by optimizing the available force fields (or both). First, you will investigate how much higher-order effects play a role in DFT predictions of elastic constants. Typical deficiencies of current models include anharmonicity and Pulay stress. For most applications, they do not matter much, but the shallow energy profile of MOFs enhances their effects. In a second stage, you will apply this knowledge to find a computationally feasible routine for predicting accurate elastic constants with DFT and compare to available force fields. If this appears to be impossible, you can also generate a limited number of reference data, with which existing force fields can be further optimized. Finally, your optimized approaches can be used in state-of-the-art MOF applications.

The thesis proposal focuses on two applications. MIL-53(Al) is the prototype example of a breathing MOF. Many variants of MIL-53(Al) can be created by functionalizing the linker (e.g. by replacing a hydrogen atom of benzene with an amine group). By accurately predicting the elastic constants, you can therefore establish whether the modified MIL-53(Al) will still breathe or not. A second application focuses on the opposite objective: how can you make a MOF as rigid as possible? Zirconium-based frameworks are promising for industrial purposes, but they have a poor resistance to mechanical processing. Literature showed favourable effects when modifying linkers with trifluoroacetic acid (TFA) [4], but it is still unclear how other linker modifications or even other linkers can attain the same effect.

Engineering & Physics aspects:

Physics: use of quantum and classical mechanical models for materials modelling

Engineering: application to the elastic properties of nanoporous materialsClusters: Modelling, materials, nano

- Study programmeMaster of Science in Engineering Physics [EMPHYS]Recommended coursesSimulations and Modeling for the Nanoscale, Computational Materials PhysicsReferences

[1] A. Schneemann et al., 'Flexible metal-organic frameworks', Chem. Soc. Rev. 43, 6062-6096 (2014).

[2] A. Ortiz et al., 'Anisotropic Elastic Properties of Flexible Metal-Organic Frameworks: How Soft are Soft Porous Crystals?', Phys. Rev. Lett. 109, 195502 (2012).

[3] L. Vanduyfhuys et al., 'QuickFF: A program for a quick and easy derivation of force fields for Metal-Organic Frameworks from ab initio input', J. Comput. Chem., in press (2015).

http://dx.doi.org/10.1002/jcc.23877

[4] B. Van de Voorde et al., 'Improving the mechanical stability of zirconium-based metal-organic frameworks by incorporation of acidic modulators', J. Mater. Chem. A 3, 1737-1742 (2015).