Simulation of thermo-mechanical properties of Environmentally Acceptable Lubricants

Simulation of thermo-mechanical properties of Environmentally Acceptable Lubricants

Promotor(en): D. Fauconnier, T. Verstraelen /28609 / Model and software developmentBackground and problem

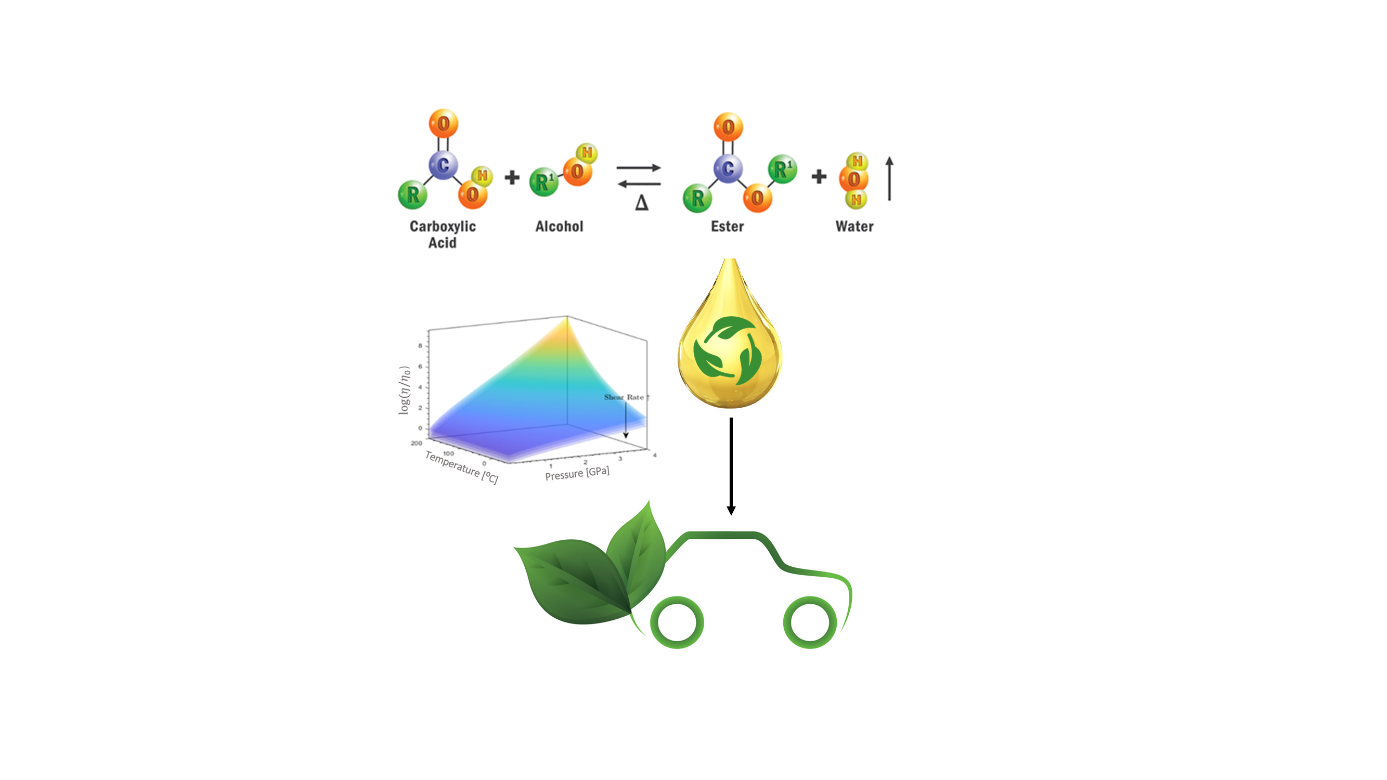

Friction and wear are one of the most fundamental sources of worldwide energy loss[1]. Hence, adequate lubrication is crucial to minimize friction and wear, assuring optimal energetic performance, durability, reliability, and finally a guaranteed expected lifetime of machine components. Conventional lubricant oils, such as n-alkanes, are obtained from the refinement of crude oil and among them petroleum-based mineral oils. Because their refinement process is relatively simple, these are the cheapest base oils on the market. Significant disadvantages of conventional lubrication oils are their low biodegradability and eco-toxicity. For example, oil leakage poses a serious risk to the environment. Biodegradable and environmentally non-toxic lubricants mitigate this risk and therefore gained considerable traction in recent years[2]. Besides being environmentally friendly, bio-lubricants also exhibit excellent properties: their high lubricity, high viscosity index and flash point outperform mineral oils. Among various commercial bio-lubricants, synthetic esters are the most common. Many types of synthetic esters can be produced (such as monoesters, diesters, polyol esters) and these are used in a wide range of applications, including automotive, aviation and marine industries. Gears and bearings operate under the so-called Thermo-Elasto-Hydrodynamic lubrication (TEHL) regime in which solid surfaces are separated by an oil film of < 1 μm thickness. In this regime, lubricants can experience ultra-high pressures (1-4 GPa), very high shear rates ((>108 s-1) and high temperatures (> 120 °C). Fundamental experimental rheological investigations of lubricants at ultra-high pressures (> 0.8 GPa) and high shear rates representative for TEHL contacts are extremely challenging. Hence, Molecular Dynamics (MD) simulations gained considerable interest in the recent decade, motivated by the fact that atomic-scale processes are the underlying cause of many macroscopic tribological phenomena. However, in most of the literature, only petroleum-based mineral oils are used as studied with MD simulations [3].

Goal

The goal of this thesis is to investigate the properties of environmentally accepted lubricants (EALs) in order to provide an ecological alternative to existing petroleum-based lubricant oils. Molecular Dynamics simulations will be used to calculate the properties of EALS such as density, viscosity and thermal conductivity under relevant machine operating conditions. We intend to use the well-established open-source LAMMPS code for MD Simulations. Various force fields (such as OPLS, DREIDING, COMPASS, AMBER) will be benchmarked in terms of their accuracy to predict the thermomechanical properties of bio-lubricants.

Task involved:

- Setup molecule, select appropriate force field…

- Setup computational box with initial distribution

- perform simulations from different statistical initial conditions using LAMMPS

- Statistical post-processing using in-house tools to extract thermomechanical properties.

- Study programmeMaster of Science in Engineering Physics [EMPHYS], Master of Science in Electromechanical Engineering [EMELME], Master of Science in Physics and Astronomy [CMFYST]KeywordsEnvironmentally accepted lubricants, Sustainability, Molecular dynamics simulations, thermomechanical propertiesReferences

[1] K. Holmberg and A. Erdemir, “Influence of tribology on global energy consumption, costs and emissions,” Friction , vol. 5, no. 3, pp. 263–284, 2017, doi: 10.1007/s40544-017-0183-5.

[2] MJG Guimarey, DEP Gonçalves, JM Liñeira, MJP Comuñas, J. Fernández, and JHO Seabra, “Lubricant properties of trimethylolpropane trioleate biodegradable oil : High pressure density and viscosity , film thickness , Stribeck curves and influence of nanoadditives,” vol . 335, 2021, doi: 10.1016/j.molliq.2021.116410.

[3] JP Ewen, HA Spikes, and D. Dini, “Contributions of Molecular Dynamics Simulations to Elastohydrodynamic Lubrication,” Tribol. lett. , full. 69, p. 24, 2021, doi: 10.1007/s11249-021-01399-w.