Rheological Modelling of Lubricants by Molecular Dynamics

Rheological Modelling of Lubricants by Molecular Dynamics

Promotor(en): D. Fauconnier, T. Verstraelen /19MODEV10 / Model and software developmentElasto-hydrodynamic lubrication (EHL) is a lubrication regime characterized by a thin liquid film typically in between highly-loaded, non-conformal contacting surfaces in relative motion to each other. The film thickness then reaches the order of the surface roughness (50nm-1µm, depending on the surface finishing), without the occurrence of mechanical contacts between microscopic surface asperities. In the narrow contact geometry enclosed by the contacting bodies, extreme hydrodynamic pressures (order GPa) can occur, resulting in significant local deformation of the contact surfaces (hence the name Elasto-Hydrodynamic lubrication), and local compression of the liquid lubricant molecules up to the point of solidification. This implies that the density and viscosity of the lubricant dramatically increase from a macroscopic point of view.

Moreover, as the shear rates increase inversely proportional with the film thickness, they can rise up to values over 106-107 s-1. This implies that neighbouring molecules in the thin lubricant film are subject to a very large stresses gradients, resulting on a macroscopic scale typically in non-Newtonian shear-thinning behaviour (viscosity decreases under shear strain). Furthermore, the large shear stresses may induce slipping of the first layer of lubricant molecules along the (metal) solid surface.

Due to the high pressures and high shear rates in EHL contacts, and thus intensified molecular interactions, the temperature of the thin lubricant film increases dramatically, leading to a reduction in viscosity and density. Besides the macroscopic mechanical properties such as density and viscosity, also the macroscopic thermal properties, such as thermal conductivity and heat capacity depend on local pressure, shear rate and temperature.

It is clear that proper description of the rheological, thermal and compressible properties of the lubricant is mandatory in order to fully grasp the physical mechanisms involved in EHL, and in order to build accurate and reliable computational macroscale models. Typically semi-empirical models or curve-fittings are adopted for the description of thermo-physical properties of a specific lubricant, which are based on numerous, expensive and cumbersome experiments obtained for a particular lubricant and under specific conditions. Note that those conditions are typically far from the in-situ extreme conditions encountered in EHL contacts, i.e. high pressures (GPa range), high temperatures and high shear rates (106-107 s-1), as the traditional experimental equipment (rheo-meters etc..) is not accommodated for these conditions. Such models have limited applicability.

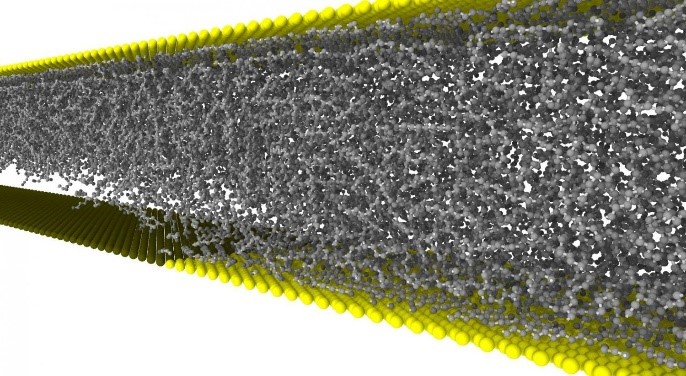

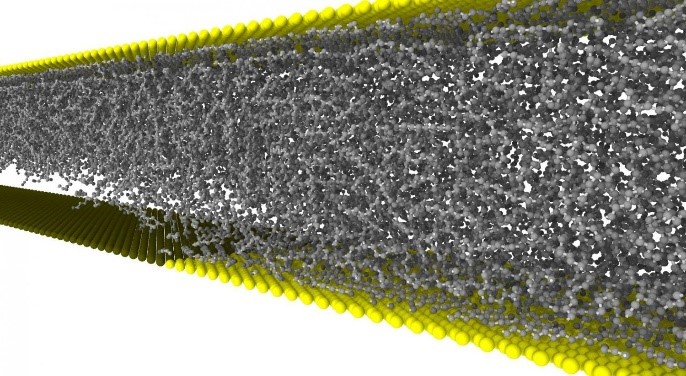

Since the turn of the century, however, there has been an exponential increase of interest in Molecular dynamics (MD) simulation as a more sophisticated approach to study interfacial phenomena and thin film rheology in the field of Tribology. In MD, the atoms in the solid surfaces and the confined lubricant are the basic particles and their temporal evolution is described by Newton’s equation of motion, using inter- and intramolecular force fields to compute forces acting on the atoms at each time step.

objectives

The main objective is to characterize the macroscopic thermo-physical properties of a lubricant in a wide pressure, temperature and shear rate range relevant for hydrodynamic and elasto-hydrodynamic lubrication. These properties include,

- Density,

- Viscosity,

- Thermal conductivity,

- Heat capacity

- Limiting shear stress and wall slip velocity

- Vaporous CavitationWe intend to use the open-source C++ LAMMPS package for the non-equilibrium MD simulations. We focus on water and/or synthetic lubricants which consist of long - possibly branched - alkane chains (C20H42 – C40H82). The lubricant is modelled in a fully 3D periodic box of lubricant molecule. The strain rate is imposed, as well as the temperature and the hydro-dynamic pressure, by respectively a thermostat (e.g. Nosé-Hoover) and barostat (e.g. Parrinello-Rahman). Volumetric changes of the MD system are directly related to the density, whereas the calculated shear stress allows to extract the viscosity after statistical averaging.

Motivation Applied Physics

The physics aspect of this proposal is that a microscopic physical model for interatomic interactions is used to predict and understand properties (with molecular simulation and statistical mechanics) of a lubricant under conditions that are experimentally inaccessible. The results will be immediately relevant for the development of new lubricants, which is a typical engineering problem.

- Study programmeMaster of Science in Engineering Physics [EMPHYS], Master of Science in Electromechanical Engineering [EMELME]ClustersFor Engineering Physics students, this thesis is closely related to the cluster(s) NANO, MODELLING, MATERIALSKeywordsRheology, Lubricants, Molecular dynamics