Reactive Simulations of the Pyrolysis and Combustion Processes of Pesticides: Cyflufenamid as a Case Study

Reactive Simulations of the Pyrolysis and Combustion Processes of Pesticides: Cyflufenamid as a Case Study

Promotor(en): T. Verstraelen, M. Sabbe /28194 / Chemistry & Biochemistry, Model and software developmentBackground and problem

Activated carbon is commonly used to remove hazardous organic compounds, such as pesticides, from waste water streams before release into the environment. [1] Desotec, [2] industrial partner to this project, specializes in reusable activated carbon filters through an advanced recycling set-up. The set-up involves non-catalytic pyrolysis at over 850 °C, followed by a combustion process at maximum 1100 °C. The operating conditions need to be tuned appropriately such that carbon is completely reactivated, while the hazardous compounds that are released from the filters need to be properly destroyed to fully close the cycle. Specifically, fluoride-based pesticides are difficult to treat because of the strong carbon-fluoride bond. This project will focus on the pyrolysis and combustion process of a specific pesticide, cyflufenamid, as a case study.

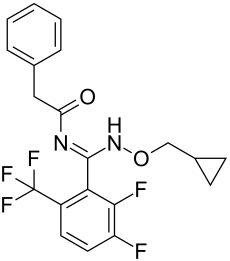

Figure 1: The chemical structure of Cyflufenamid.

Goal

The goal of this thesis is to gain a better understanding of the pyrolysis and combustion of cyflufenamid at realistic operating conditions. This will be done by performing reactive molecular dynamics simulations at the Center for Molecular modeling. Simulations will be performed using the ReaxFF force field, commonly applied in pyrolysis and combustion processes at high temperatures. [3] To unravel the associated reaction network, including reactants, transitions states and reaction products, the results will be analyzed using ChemTraYzer. [4] The output of ChemTraYzer will be post-processed with quantum-chemical methods to derive parameters for a kinetic model, developed at the Laboratory for Chemical Technology. [5]

The Center for Molecular Modeling has a proven track record in reactive molecular dynamics simulations, is actively involved in the development of ReaxFF force fields, and has ongoing collaborations with the company SCM (Amsterdam, ReaxFF software) and Prof. Leonhart (RWTH Aachen, ChemTraYzer). The Laboratory of Chemical Technology specializes in the quantitative prediction of chemical reaction rates and development of advanced kinetic models.

- Study programmeMaster of Science in Chemical Engineering [EMCHEM]KeywordsPyrolysis, CombustionReferences

[1] I. Saleh et al., Environmental Technology & Innovation, 19, 101026 (2020)

[2] www.desotec.com

[3] Z. Qifan et al., Combustion and Flame, 198, 146 (2018)

[4] L. Krep et al., Journal of Chemical Information and Modeling, published online (2022)

[5] M. Sabbe et al., Catalysis Science & Technology, 7, 5267 (2017)