One crystal, two phases: Designing phase coexistence in metal-organic frameworks for nanosensing and -actuating

One crystal, two phases: Designing phase coexistence in metal-organic frameworks for nanosensing and -actuating

Promotor(en): V. Van Speybroeck, S.M.J. Rogge /28140 / Nanoporous materialsBackground and problem

Next-generation nanosensing and -actuating materials should be able to efficiently and reliably transform well-defined atomic-level stimuli into a macroscopic response or an observable change in the material’s structure. Soft porous crystals (SPCs) or flexible metal-organic frameworks (MOFs) are materials that are ideally suited for this task, as they undergo large-amplitude phase transformations between multiple phases under the influence of external stimuli such as temperature, pressure, or adsorption. For instance, DUT-49(Cu) has been proposed for gas-releasing rescue systems given its unique potential for ‘anomalous’ negative gas adsorption (NGA).1 However, in order to design these promising materials for specific applications, it is crucial to understand the origin of this cooperative behavior and rationalize how this macroscopic spatiotemporal response can be tuned by introducing specific building blocks in the material. The NGA phenomenon in DUT-49(Cu), for instance, was experimentally observed to critically depend on the size of the MOF crystal, an effect that remains elusive to date and precludes its full exploitation in applications.2

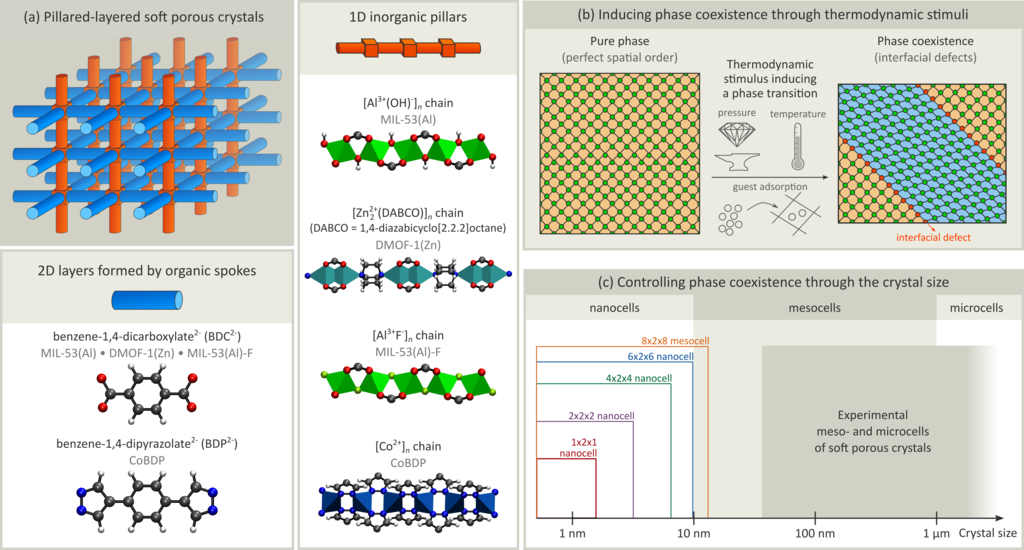

To obtain insight in these elusive but highly attractive size-dependent phase transitions in SPCs, we recently investigated a series of MOFs (see Figure 1a) at length scales going substantially beyond the nanocells that are typically simulated (see Figure 1c).3,4 In this way, we demonstrated that phase transformations in MOFs do not occur collectively, but rather proceed in a stepwise fashion in which specific regions of the MOF crystal undergo a phase transition first. During the transformation, multiple phases temporarily coexist in the same MOF crystal, leading to interfacial defects (see Figure 1b) and associated strain fields that affect the materials’ spatiotemporal response. We furthermore rationalized that this observed phase coexistence could be stabilized through carefully controlling the external stimuli, resulting in a MOF crystal that exhibits the attractive properties of both single phases.3 Given that phase coexistence moreover depends on the crystallite size, it forms a possible explanation for the size-dependent structural flexibility in SPCs.

Figure 1: (a) Structure of several soft porous crystals, (b) exhibiting phase coexistence under specific temperature, pressure, and guest loading conditions. (c) Investigating phase coexistence requires substantially larger SPC models, in line with experiment. Figure reproduced from ref. 3 with permission of SpringerNature.

Goal

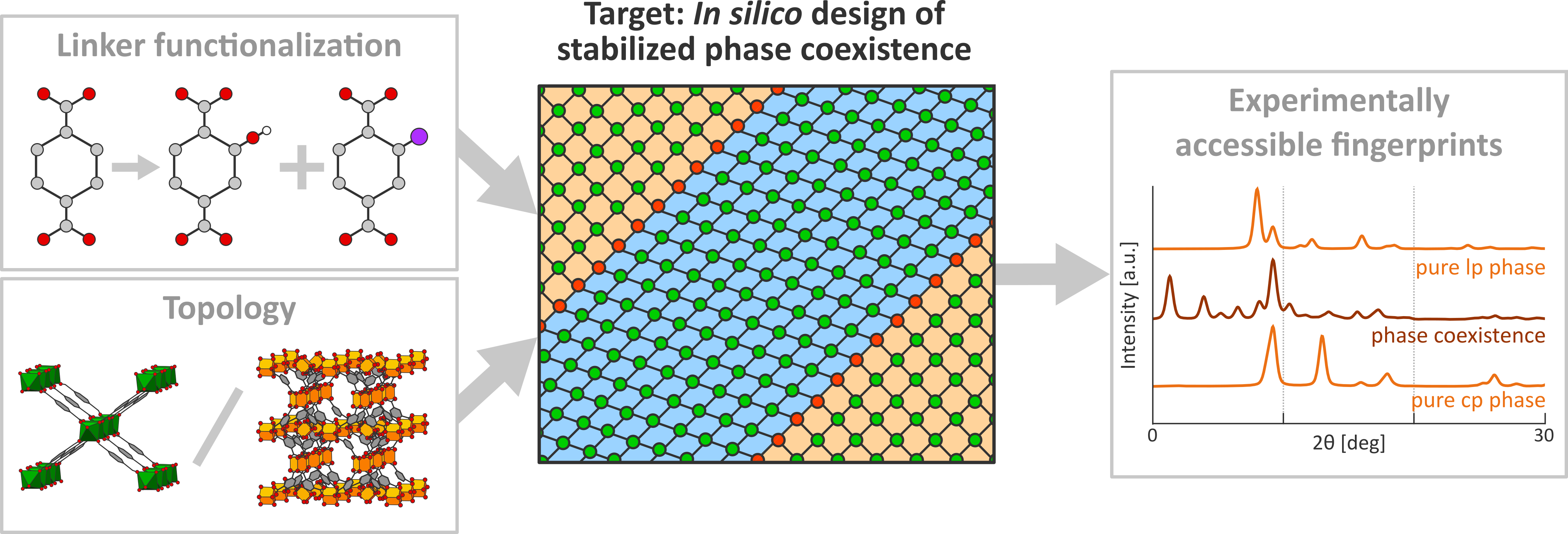

In order to fully understand and design phase coexistence as a new pathway to design the spatiotemporal response of defect-engineered MOFs, three key questions need to be answered (see Figure 2):

- Can the introduction of small alterations in the MOF building blocks, such as linker functionalization, expand the window of thermodynamic conditions under which phase coexistence can be stabilized?

- Can phase coexistence exist in MOFs exhibiting topologies other than the winerack topology (e.g., ZIF-4, ZIF-7, DUT-49) or even in other materials such as covalent-organic frameworks (e.g., COF-300), thus providing evidence for a more fundamental mechanism for phase coexistence?

- Do there exist experimentally accessible spectroscopic fingerprints linked to phase coexistence that can be predicted via operando theoretical approaches and that reveal the spatiotemporal response of the material under realistic external conditions?

Figure 2: Overview of the workflow adopted to design and characterize stable phase coexistence in soft porous crystals.

In this thesis, it is the goal to explore these fundamental questions by extending our earlier thermodynamic protocol using flexible and ab initio-derived force fields for mesosized MOF crystals.3 To reach these challenging length scales (> 10 nm), both in-house developed software as well as the versatile OpenMM simulation toolkit will be used, as the latter may provide an extra order-of-magnitude increase in length scale.4 First, the impact of functionalizing the organic ligands with, e.g., –OH and –Br groups on the emergence of phase coexistence in MIL-53 will be rationalized. These groups provide both steric hindrance–favoring the open-pore configuration–as well as attractive interactions that favor the closed-pore configuration; judiciously positioning these groups in the framework may hence culminate in a substantially expanded stability window for phase coexistence. Second, ZIF-4, ZIF-7, and COF-300 will be investigated as framework architectures that exhibit a rich polymorphism that is fundamentally different from the earlier investigated winerack-type MOFs, allowing for more complicated forms of phase coexistence. The obtained thermodynamic insight will form a crucial step forward to consciously design spatial disorder in framework materials and exploit the phenomenon for applications in nanosensing and -actuation

- Study programmeMaster of Science in Engineering Physics [EMPHYS], Master of Science in Physics and Astronomy [CMFYST]Keywordsnanosensors, phase coexistence, Metal-organic frameworks, longer length scale, Flexibility, cooperative phenomenaReferences

1S. Krause, V. Bon, I. Senkovska, U. Stoeck, D. Wallacher, D.M. Többens, S. Zander, R.S. Pillai, G. Maurin, F.-X. Coudert, S. Kaskel, Nature 532: 348, 2016.

2S. Krause, V. Bon, I. Senkovska, D.M. Többens, D. Wallacher, R.S. Pillair, G. Maurin, S. Kaskel, Nat. Commun. 9: 1573, 2018.

3S.M.J. Rogge, M. Waroquier, V. Van Speybroeck, Nat. Commun. 10: 4842, 2019.

4S. Vandenhaute, S.M.J. Rogge, V. Van Speybroeck, Front. Chem. 9: 718920, 2021.