Nanoscale simulations of lubricants and lubricant additives

Nanoscale simulations of lubricants and lubricant additives

Promotor(en): T. Verstraelen, D. Fauconnier /25412 / Model and software developmentBackground and problem

The rising demand to reduce energy consumption and increase efficiency in engineering systems requires a deep understanding of lubricant behavior to reduce friction. Understanding the interaction between engine components and lubricant molecules at atomistic-level is very crucial to gain an insight on preventing the energy loss in the machine components. Since this understanding presents challenges in the experimental point of view, computer simulations are widely preferred to develop an interpretation for this type of tribological problems in recent decades. Quantum Mechanical (QM) techniques are very effective way to study atomistic behavior of variety of systems and have been extensively used to investigate the interaction of lubricant molecules with solid surfaces as well as lubricant additives such as Organic Friction Modifiers (OFMs). OFMs are generally polar molecules that form strong layers hence prevent direct metal-metal asperity contacts. Within the class of many different additives, they are widely preferred as key additives in lubricant oils used several machine components such as bearing, gears and engines for the last two decades because they solely contain C, H, O and N atoms which makes them environmentally non-harmful. Although, OFMs are generally believed to reduce friction coefficient in the boundary lubrication regime, recent studies have shown that they also help to reduce friction in Elasto-Hydrodynamic Lubrication (EHL) regime they are widely preferred as key additives in lubricant oils used several machine components such as bearing, gears and engines for the last two decades because they solely contain C, H, O and N atoms which makes them environmentally non-harmful. Although, OFMs are generally believed to reduce friction coefficient in the boundary lubrication regime, recent studies have shown that they also help to reduce friction in Elasto-Hydrodynamic Lubrication (EHL) regime they are widely preferred as key additives in lubricant oils used several machine components such as bearing, gears and engines for the last two decades because they solely contain C, H, O and N atoms which makes them environmentally non-harmful. Although, OFMs are generally believed to reduce friction coefficient in the boundary lubrication regime, recent studies have shown that they also help to reduce friction in Elasto-Hydrodynamic Lubrication (EHL) regime, where gears and bearings operate , as a result of larger slip lengths. Hence, it is now believed that lubricant additives will provide improved performance for machine components in all operating conditions.

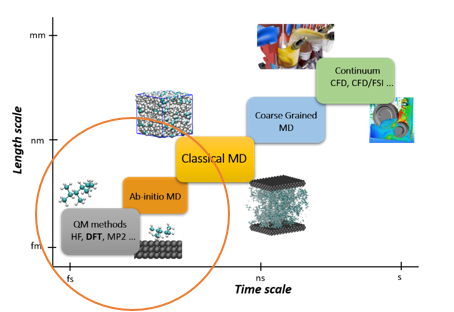

Among QM techniques, Density Functional Theory (DFT) is a powerful technique for studying adsorption of lubricant molecules on solid surfaces as well as reactivity of lubricant additives and it is applicable to broad range of systems without reparameterization. However, it requires relatively large computational cost roughly scales as ≈O(Ne)3. This generally limits DFT to study static properties of systems. Force-field (FF) models can evaluate the atomic forces at a much lower cost than DFT. With force fields, it becomes feasible to perform Molecular Dynamics (MD) simulations at the operating conditions of machine components. In addition, with the help of reactive force-fields (such as ReaxFF), reactivity of lubricant additives can also be studied with MD simulations.

Hence, both DFT and FF techniques are powerful tools to develop bottom-up understanding for tribological systems and can be effectively used to design lubricants to reduce friction and wear, therefore energy consumption in the machine components.

Goal

The main purpose of this study is to investigate the nature of interaction between solids and lubricant molecules first using DFT technique. In the first stage, we would like to focus on some properties of single-molecule lubricants (i.e. n-alkanes CnH2n+2) and solid surface particularly α-iron(III) oxide (α-Fe2O3) to better represent engine components that are generally made up of steel. This form of iron oxide is known as hematite being the most abundant form which is mined as the main ore of iron. After obtaining adsorption characteristics for this system, lubricant additives in particular OFMs and their effect on adsorption characteristics will be considered. Main properties of interest include

- Adsorption energies of different single-molecule lubricants on solid surfaces

- Friction coefficient

- Effect of lubricant additives on adsorption characteristics and friction coefficient

For the investigation of adsorption characteristics at DFT level, we intend to use open-source plane-wave Quantum Espresso code with Hubbard corrections (i.e. DFT + U) to account for electronic correlations in the d orbitals of iron as well as dispersion corrections to better model long range interactions. In the later stage, force-field MD simulations will be performed to investigate these tribo-systems under more realistic temperature and pressure conditions using well-established open-source LAMMPS code suite. In the end, this comprehensive study will provide a detailed understanding of the friction phenomenon at atomistic-scale using a bottom-up approach.

- Study programmeMaster of Science in Engineering Physics [EMPHYS], Master of Science in Physics and Astronomy [CMFYST]KeywordsLubricants, Nanotribology, Tribochemistry, Density functional theory, Molecular dynamics simulations