Molecular Modeling of the Hydrolysis of Potent Implantable Drug Delivery Devices

Molecular Modeling of the Hydrolysis of Potent Implantable Drug Delivery Devices

Promotor(en): V. Van Speybroeck, S. Catak /15_CHEM03 / Chemistry & BiochemistryThis thesis is conducted in collaboration with DSM Research, The Netherlands.

Implantable drug delivery devices offer several advantages over conventional oral or parenteral dosage forms. Firstly, implantable devices allow site specific drug administration where the drug is most needed. Examples include implants used in the treatment of brain tumors or prostate cancer. This may also allow for significantly lower doses of the drug, which can minimize potential side effects. Secondly, implantable devices allow for sustained release of a therapeutic agent. The last and perhaps most important advantage is patient compliance, as the treatment regimen associated with an implantable device is generally less burdensome than pills or injections.

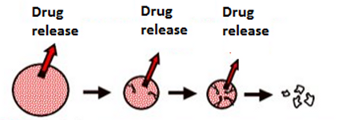

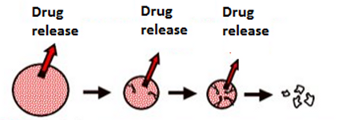

Implantable drug delivery devices based on bio-degradable polymers allow for avoidance of re-interventions related to removal of the drug delivery implant, and therefore minimize risk of complications and adverse events associated with long term implantable materials. Such polymers release drugs by diffusion or by erosion of the polymer (Figure 1). However, these benefits have to be weighed against potential risks caused by the degradation products that are formed. Next to the high standards for biocompatibility which apply for these materials; the products of polymer bio-degradation and their biocompatibility and clearance from the body need to be understood as well.

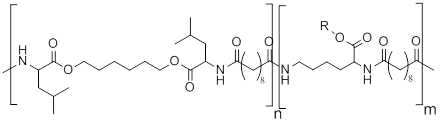

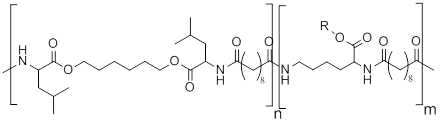

Figure 1. Drug release from a polymeric particle due to diffusion and/or degradation of the polymeric matrix.Amino acid based poly(ester amides) (PEAs) are random co-polymers that are based on natural building blocks (Figure 2) and therefore offer several advantages over the traditional drug delivery technologies. In addition to biocompatibility and biodegradability, they can be processed to a variety of forms such as particles, coatings, monoliths and fibers. Their mechanical properties can be easily tuned, covering a broad range of application requirements and most importantly, PEA polymers degrade at physiological conditions and are expected to result in natural biocompatible products.

However, the PEAs contain several hydrolysable linkages that will hydrolyze with different rates.

Figure 2. Amino acid based biodegradable polyester amide for drug deliveryConsequently, several structures of which the health risks are not known yet will be formed during the degradation.

At the moment, several experiments are running to determine the hydrolysis products that are formed. However, these experiments are tedious and the analysis of the formed reaction mixture is difficult.

Molecular modeling can help to better understanding the hydrolysis and predict the type of hydrolysis products (oligomers) that are formed.

Goal As discussed above, the accurate identification of the potential polymer degradation products is an essential part of its biocompatibility assessment. As this is difficult experimentally, the idea of the present project is to use molecular modeling to determine the difference in hydrolysis rate of the different units present and based on these calculations predict which fragments are formed as a function of time.

These results can be validated with the limited amount of experimental data available. Two molecular modeling approaches are envisaged:

1. A detailed study of the hydrolysis reaction pathways by modeling relevant reactants, transition states and products involved in the hydrolysis reaction.

2. Usage of linear free energy relationships, i.e. establishing appropriate linear relationships to link changes in the hydrolysis rate constant to changes in a specific equilibrium constant as the structure of the reagents is altered.This research will be conducted at the Center for Molecular Modeling, in collaboration with DSM.

- Study programmeMaster of Science in Chemical Engineering [EMCHEM], Master of Science in Chemistry [CMCHEM]KeywordsImplantable drug delivery devices, Bio-degradable polymers, Natural building blocks, Hydrolysis, Molecular modeling