An international collaboration between researchers of the Multifunctional Materials & Composites (MMC) Laboratory at the University of Oxford (Yueting Sun, now at the University of Birmingham, Clive R. Siviour, and prof. Jin-Chong Tan) and the Center for Molecular Modeling (CMM) at Ghent University (dr. Sven M.J. Rogge, Aran Lamaire, dr. Steven Vandenbrande, dr. Jelle Wieme, and prof. Veronique Van Speybroeck) demonstrated a new conceptual type of reusable shock absorber. By harnessing the energy of mechanical impacts to force water in the hydrophobic cages of nanoporous materials such as ZIF-8, large shocks can be efficiently absorbed. Thanks to a combined experimental and computational approach, the study also formulated design rules that led to the identification of twenty more promising materials for shock absorption. The work was recently published in Nature Materials and was supported, among others, by 4 FWO (post-)doctoral fellowships and 2 ERC Consolidator grants. News stories about this article appeared on VRT NWS and in New Scientist.

New generation of shock absorbers

Known materials that need to capture large shocks, such as guard rails or helmets, deform strongly to neutralize the mechanical energy of such a shock. In most cases, this means that the materials do not return spontaneously to their original state after the shock has disappeared again. As a result, they lose the ability to absorb further shocks. Research performed at the Center for Molecular Modeling (CMM), led by prof. Van Speybroeck, and the University of Oxford now reveals a new mechanism that makes shock absorbers both reusable and much more efficient.

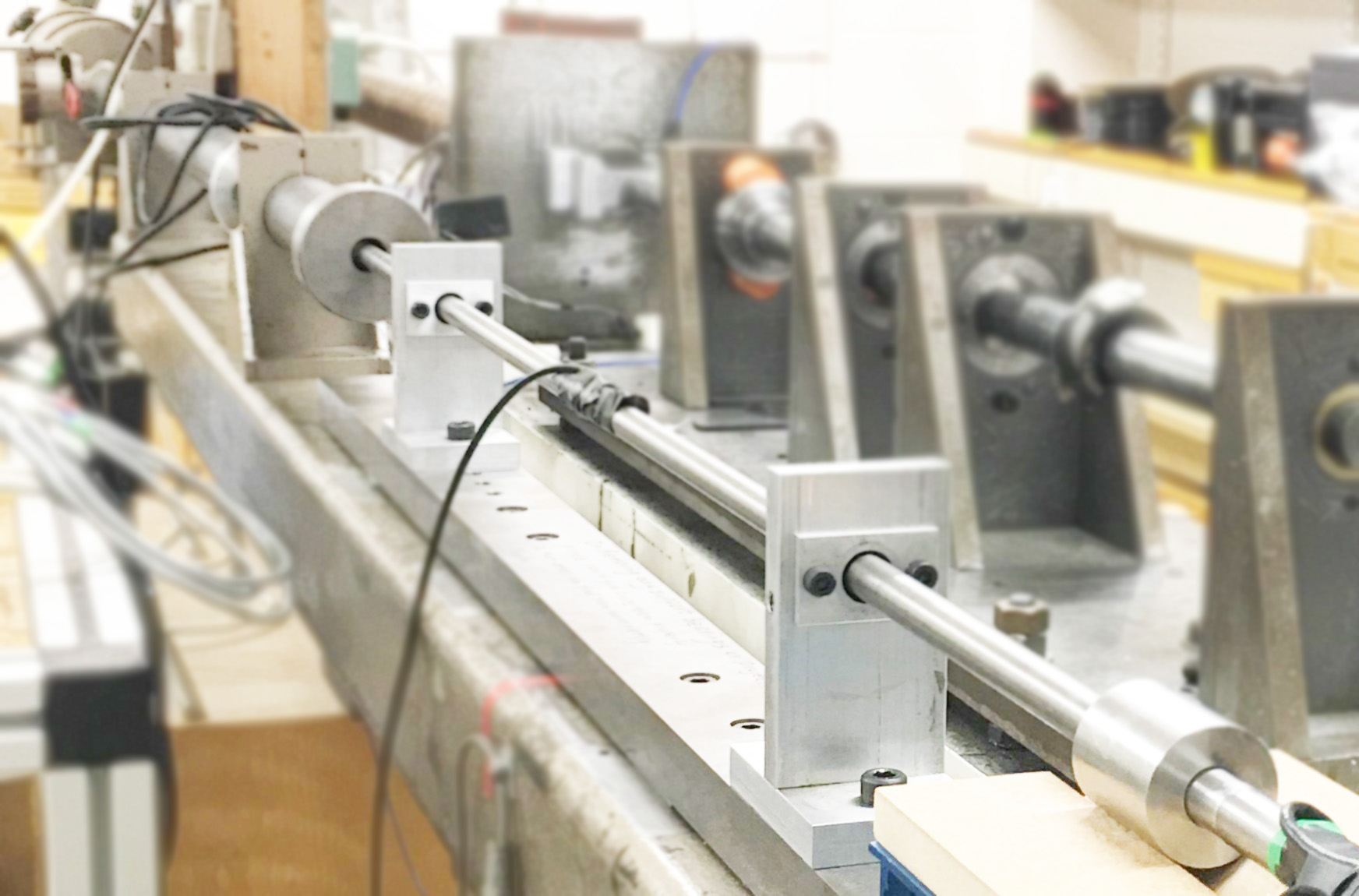

The experimental high-rate setup, courtesy of dr. Yueting Sun (University of Birmingham)

These new shock absorbers consist of two elements: on the one hand water, and on the other hand a nanoporous material that consists of interconnected hydrophobic cages. Upon a mechanical impact, the energy of this shock is used to force water in the hydrophobic cages. Moreover, the researchers observed that the higher the impact rate, the more energy the material absorbs. Once the shock disappears, water again extrudes from the cages, and the whole absorption cycle can start over again.

What makes these materials so efficient?

Researchers at the University of Oxford observed this new mechanism first in ZIF-8, a so-called metal-organic framework with a structure that closely resembles that of zeolites. To understand why this nanoporous material can absorb mechanical shocks so efficiently, and especially why it does so more efficiently the higher the impact rate, researchers at the CMM performed several challenging quantum mechanical calculations.

These calculations demonstrated the key role played by the very specific ZIF-8 structure. Because the material consists of interconnected hydrophobic cages, water never introduces spontaneously in these cages. Only when there is sufficient pressure on the material, for instance, because of a mechanical shock, the first water molecules start entering the material’s cages, despite its hydrophobicity. Hydrogen bridges then ensure that the molecules confined in the cages organize in small clusters. As soon as such a cluster becomes sufficiently large – from about five molecules onwards – it becomes much easier to intrude more water molecules in the cages until they finally fill the whole material. This process does take some time. As a result, if the mechanical shock has too high an impact rate, there is insufficient time to form this type of clusters, and even more energy of the mechanical shock is needed to force water inside the cages. This explains the higher efficiency of these materials at high-rate impacts.

What’s next?

Based on these simulations, the researchers derived a set of design rules to develop shock absorbers that harness this specific mechanism. The most important design rule is that such materials need to consist of hydrophobic cages, such that water does not intrude spontaneously. Furthermore, these cages need to be interconnected via apertures that are sufficiently large so that water molecules can move from one cage to the other. Finally, the larger the cages, the more water molecules they can eventually accommodate, and so the more mechanical energy of the shock they can neutralize. Based on these design rules, we discovered about twenty materials in total that are not used as shock absorbers for the moment, but that would be in fact very efficient for this task. Some of those materials we have now also tested, with very promising results.

Technical info

These results were published in Nature Materials.

High-rate nanofluidic energy absorption in porous zeolitic frameworks

Yueting Sun, Sven M. J. Rogge, Aran Lamaire, Steven Vandenbrande, Jelle Wieme, Clive R. Siviour, Veronique Van Speybroeck, and Jin-Chong Tan

Nature Materials, 10.1038/s41563-021-00977-6

Dr. ir. Sven Rogge, ir. Aran Lamaire, prof. dr. ir. Veronique Van Speybroeck

Center for Molecular Modeling

Technologiepark 46, 9052 Zwijnaarde

M +32 (0)478 82 34 19