While metal-organic frameworks (MOFs) form promising materials to extract water from the air in the desert, to store dangerous gases or to power hydrogen-based cars, they are often very fragile. In collaboration with the University of Cambridge, researchers at Ghent University have developed a multi-level machine learning algorithm to computationally predict the mechanical properties of these materials and identify those MOFs that are sufficiently stable for practical applications.

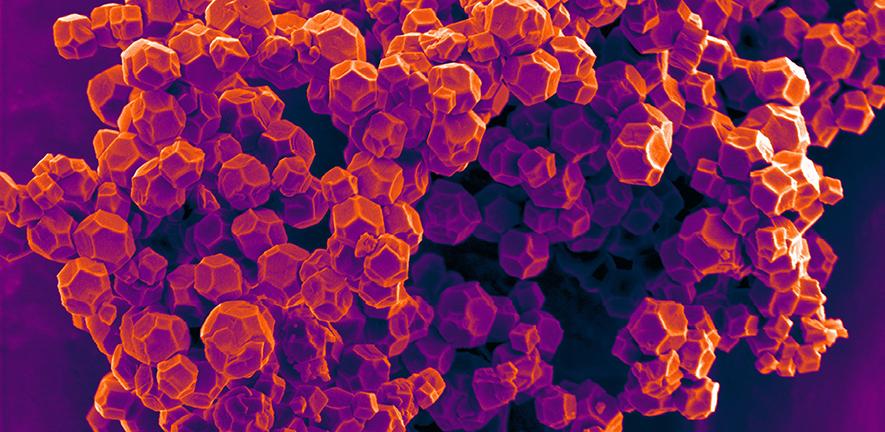

Image courtesy of prof. David Fairen-Jimenez (University of Cambridge)

Molecular K’NEX

Similar to K’NEX or Lego sets, MOFs are functional structures assembled from a combination of building blocks. By precisely selecting building blocks with appropriate properties and assembling them in a periodic material, researchers can design MOFs with vastly different structures and functionalities for applications in fuel storage, detoxification of hazardous environments, or carbon capture. However, as with K’NEX or Lego, the stability of the MOF is a crucial design parameter that can literally make or break the material.

For MOFs, this fragility originates from their highly porous structure and massive surface area: a MOF the size of a sugar cube laid flat would cover an area the size of six football fields. While this makes them highly effective as adsorption and storage devices, as highlighted in this EOS blog article (in Dutch), their internal pores make them also very prone to structural collapse under pressure.

MOFs under pressure

As MOFs are generally synthesized in powder form, the powder needs to be put under pressure and formed into larger, shaped pellets to be of any practical use. Due to their porosity, many MOFs are crushed in this process, wasting both time and money.

To address this problem, researchers at the University of Cambridge, Ghent University, and the Colorado School of Mines under supervision of prof. David Fairen-Jimenez and prof. Veronique Van Speybroeck developed a machine learning algorithm to predict the mechanical properties of thousands of MOFs so that only those with the necessary mechanical stability are manufactured.

Neural networks to predict stable MOFs

The project, spearheaded by dr. Peyman Z. Moghadam and dr. Sven Rogge, used a multi-level computational approach in order to build an interactive map of the structural and mechanical landscape of MOFs. First, they used high-throughput molecular simulations for 3,385 MOFs. Secondly, they developed a freely-available machine learning algorithm to automatically predict the mechanical properties of existing and yet-to-be-synthesised MOFs.

The researchers have launched an interactive website where scientists can design and predict the performance of their own MOFs. This tool will help to close the gap between experimentalists and computationalists working in this area, as it allows researchers to access the tools they need in order to work with these promising materials.

Technical info

These results were published in the inaugural edition of the Cell Press journal Matter:

Structure-Mechanical Stability Relations of Metal-Organic Frameworks via Machine Learning

Peyman Z. Moghadam, Sven M. J. Rogge, Aurelia Li, Chun-Man Chow, Jelle Wieme, Noushin Moharrami, Marta Aragones-Anglada, Gareth Conduit, Diego A. Gomez-Gualdron, Veronique Van Speybroeck, and David Fairen-Jimenez

Matter, http://doi.org/10.1016/j.matt.2019.03.002

Dr. ir. Sven M. J. Rogge, prof. dr. ir. Veronique Van Speybroeck

Center for Molecular Modeling

Technologiepark 46, 9052 Zwijnaarde

T +32 (0)9 264 65 75 | M +32 (0)478 82 34 19