Ab initio study on the mechanism and kinetics of alkene cracking in zeolite catalysts

Ab initio study on the mechanism and kinetics of alkene cracking in zeolite catalysts

Promotor(en): V. Van Speybroeck /17NANO03 / Nanoporous materialsCatalytic hydrocarbon conversion over zeolite catalysts is widely applied in chemical industry for the production of transportation fuels (gasoline, diesel, …) and base chemicals (light olefins, aromatics, paraffins, …). Alkene cracking often forms a crucial step in these processes and is therefore particularly relevant for both classical FCC processes as well as emerging alternatives, e.g., the methanol-to-olefins (MTO) process, biomass conversion,... Furthermore, olefin cracking is applied in the on-purpose propene (and ethene) production. In these technologies, less valuable C4+ alkenes are cracked to achieve high overall propene and ethene yields. Given the importance of cracking reactions, a profound understanding of the mechanism and kinetics is required to select or design the optimal performing catalyst for industrial FCC and MTO plants.

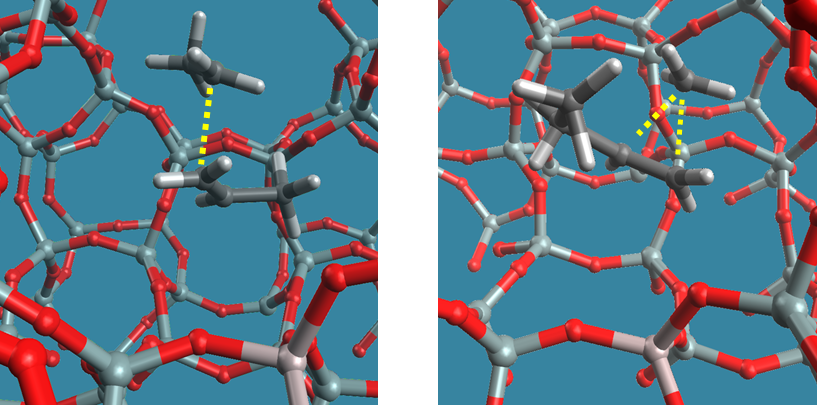

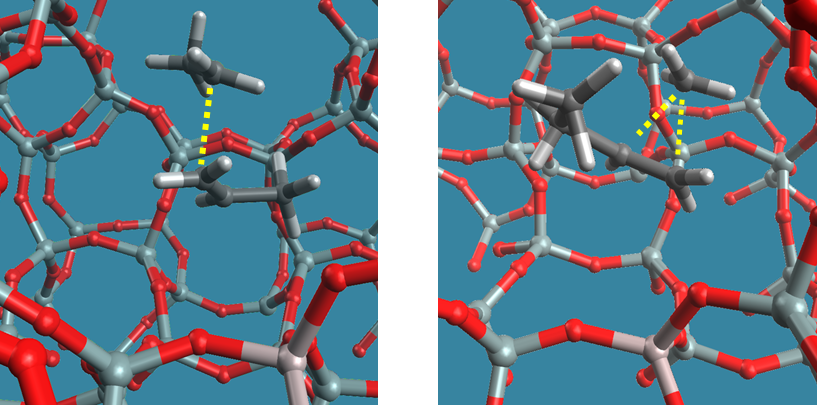

Alkene cracking occurs through a complex reaction network consisting of a multitude of hydride transfer, alkylation, isomerization and β-scission (cracking) reactions (Figure 1). Consequently, a large pool of linear and branched hydrocarbons will be formed inside the zeolite pores. Carbenium ion intermediates are known to play an active role in the cracking and isomerization reactions. The nature and stability of carbenium ions is influenced by the reaction conditions, the zeolite topology and the alkene feed. However, due to the high reactivity of the reaction intermediates, even at lower temperatures, detailed information on individual reaction steps in the network can hardly be obtained from experiments. Theoretical simulations can assist in providing fundamental insights at the molecular level and aid in understanding experimental observations.

Figure 1. Beta-scission (left) and isomerization (right) of a pentyl carbenium ion in H-ZSM-5Goal

The goal of this master thesis is to identify the prevailing cracking intermediates in H-ZSM-5 at industrial process conditions and to elucidate the pathways leading to the desired products, i.e., propene and ethene. You will perform a rigorous study on the isomerization and cracking of selected C4 – C8 alkenes. First, different isomerization steps will be investigated with advanced molecular modeling techniques to clarify the nature and stability of alkene and carbenium ion intermediates. To this end, static calculations using accurate, contemporary functionals are combined with state-of-the-art molecular dynamics simulations. Next, cracking of the identified intermediates will be studied. You will use rare-event sampling methods to unravel the underlying mechanisms and to predict the formation rates of the olefin products. Finally, the influence of temperature, zeolite topology and acidity will be assessed in order to maximize the propene yield.The Center for Molecular Modeling has ample experience in modeling of zeolite catalysis with advanced simulation techniques. The student will be actively coached to get acquainted with the multitude of available techniques to tackle the proposed problem. This thesis proposal will be conducted in close collaboration with prominent experimental partners in the field, providing an ideal opportunity to acquire valuable input and to validate the obtained results. The proposed topic is challenging and requires technical skills, creativity and chemical insight. The CMM will provide the necessary computational resources for studying this complex system.

- Study programmeMaster of Science in Chemical Engineering [EMCHEM]KeywordsZeolites, Heterogeneous Catalysis, Chemical kinetics, Computational applications